Why Rapid Tooling is a Game-Changer for Production

Traditional manufacturing faces a persistent bottleneck: waiting months for expensive, hardened steel production molds that delay product launches and increase development costs. Rapid tooling revolutionizes this timeline by providing manufacturing tools in weeks rather than months, fundamentally transforming how companies approach production readiness and market responsiveness.

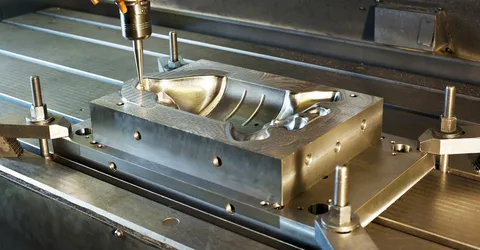

What Exactly is Rapid Tooling Technology?

Rapid tooling encompasses various techniques used to quickly create molds or tools for manufacturing processes like injection molding and die casting. This approach often utilizes additive manufacturing or soft metal materials to produce rapid tooling solutions that bridge the gap between prototyping and full production. Rapid tooling enables faster market entry while maintaining quality standards essential for commercial success.

Rapid Tooling Accelerates Market Entry

Rapid tooling delivers unprecedented speed advantages compared to traditional tooling approaches. While conventional hardened steel molds require 12-16 weeks for completion, rapid tooling solutions can be delivered in just 3-4 weeks. This dramatic timeline reduction allows companies to begin production and respond to market demands with speed that was previously impossible, providing significant competitive advantages through rapid tooling implementation.

Cost Advantages of Rapid Tooling for Bridge Production

While rapid tooling molds may not achieve the millions of cycles possible with hardened steel tools, they excel at producing hundreds to thousands of parts cost-effectively. This capability makes rapid tooling perfect for low-volume production, market testing, and pilot manufacturing runs without requiring massive capital investments. Rapid tooling reduces financial risk while enabling faster validation of market assumptions.

Encouraging Design Iteration Through Rapid tooling Flexibility

Rapid tooling significantly reduces the risk associated with design changes during development phases. When design flaws are discovered, modifying or recreating aluminum rapid tooling molds proves much faster and less expensive than modifying hardened steel alternatives. This flexibility fosters more agile development processes where rapid tooling enables continuous improvement throughout production ramp-up phases.

Rapid Tooling vs. Traditional Tooling

Rapid tooling and traditional tooling serve complementary roles in modern manufacturing. Rapid tooling delivers results in weeks versus months for traditional approaches, with lower costs but shorter mold life spanning hundreds or thousands of parts rather than millions. Traditional tooling suits mass production applications, while rapid tooling excels for prototyping, bridge production, and low-volume manufacturing where speed and flexibility outweigh ultimate production capacity.

Rapid Tooling as a Strategic Manufacturing Enabler

Rapid tooling does not replace traditional tooling but rather serves as a powerful strategic tool that de-risks product launches and enables manufacturing agility. This technology represents a key component of future manufacturing paradigms focused on responsive, on-demand production capabilities. Rapid tooling empowers companies to validate markets, refine designs, and achieve faster time-to-market while maintaining the quality standards that customers demand.